The origins of laser cleaning can be traced back to the development of lasers in the mid-20th century. Initially, lasers were primarily used for scientific and military purposes. However, as laser technology advanced, researchers began exploring its applications in various industries. The idea of using lasers for cleaning surfaces emerged in the 1990s, and over time, laser cleaning systems were developed and commercialized. The early applications of laser cleaning focused on delicate restoration projects, such as removing soot from valuable artworks or restoring historical artifacts. As the technology improved and became more affordable, laser cleaning gained popularity for industrial applications due to its precision, efficiency, and environmental friendliness. Today, laser cleaning systems are available in different configurations, power levels, and wavelengths to cater to a wide range of cleaning needs and surface types.

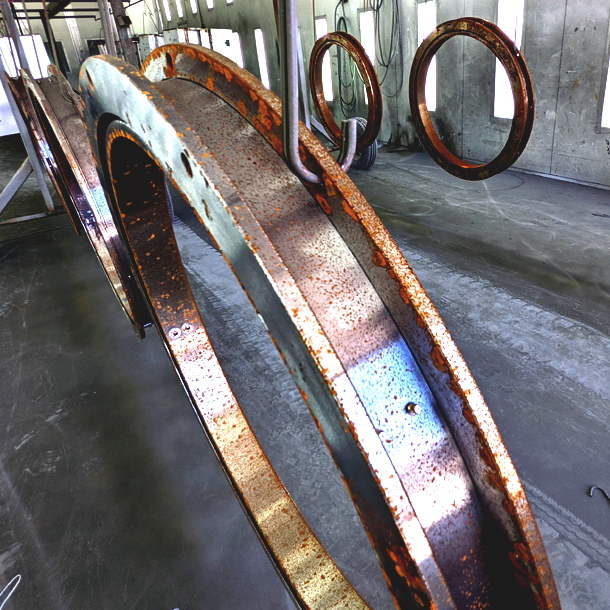

Soon, Rocklea Abrasive Blasting will be offering laser cleaning. This new technology for industrial surface cleaning will be available on almost any metal. Laser cleaning systems are a great alternative to sandblasting, dry ice blasting and other abrasive blasting techniques because they are eco-friendly, energy-efficient and much faster.

Equipment Setup: The laser cleaning equipment is set up, which includes the laser system, control unit, and safety measures. The laser system is configured based on the specific cleaning requirements, such as the power level and wavelength. Safety precautions, including wearing appropriate protective eyewear, are taken to protect the operator and ensure safe operation.

Surface Preparation: Before laser cleaning, the surface to be treated is prepared by removing loose debris, dirt, or any other loose contaminants. This may involve using brushes, compressed air, or other suitable methods to ensure the surface is clean and ready for laser cleaning.

Laser Cleaning Process: The laser beam is directed onto the targeted area of the surface. The laser energy interacts with the contaminants or unwanted materials, causing them to vaporize or sublimate. The energy from the laser is absorbed by the contaminants, while the underlying substrate reflects or minimally absorbs the laser energy, preventing damage to the surface.

Control and Monitoring: During the laser cleaning process, the operator controls and monitors the cleaning parameters. This includes adjusting the laser power, scanning speed, and focal point to achieve the desired cleaning results. The operator may need to make real-time adjustments based on the condition of the surface and the effectiveness of the cleaning process.

Post-Cleaning Inspection: Once the laser cleaning process is complete, the cleaned surface is inspected to ensure the contaminants or unwanted materials have been effectively removed. The operator may use visual inspection or other measurement techniques to verify the cleanliness and quality of the surface. If necessary, additional passes or localized cleaning may be performed to achieve the desired level of cleanliness.

It’s important to note that laser cleaning systems can vary in terms of the specific equipment and settings used. The process described above provides a general overview of the laser cleaning process, but it may be tailored or modified based on the specific requirements of the application and the capabilities of the laser cleaning equipment.

© 2024 RAB ltd | Website Design by iFactory